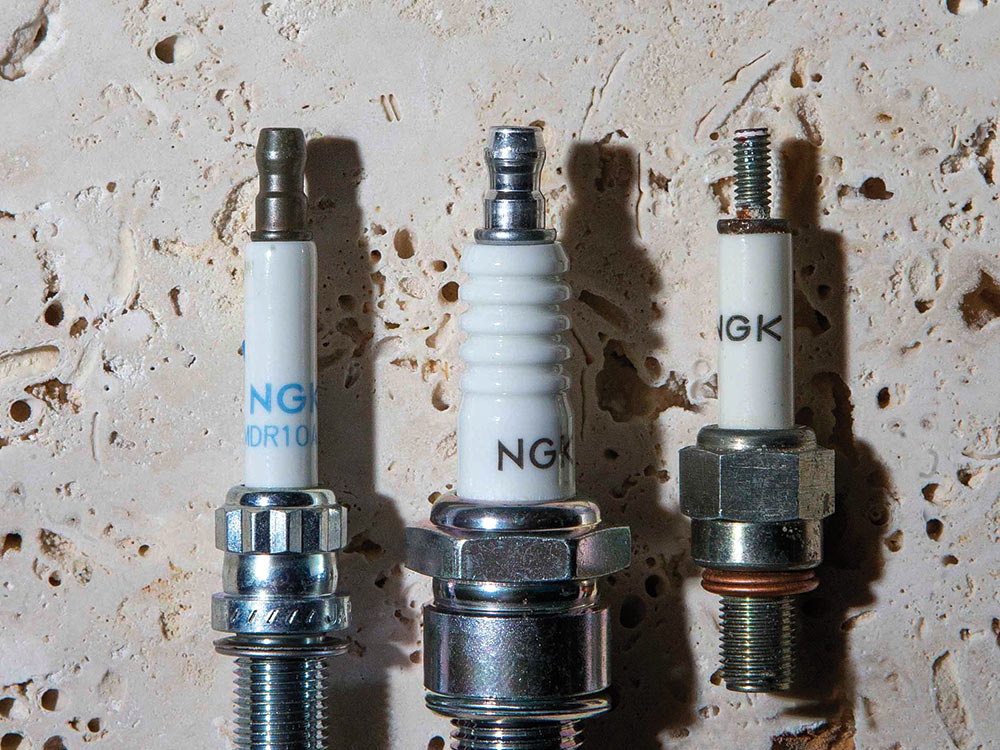

For tapered plugs, tighten by hand until they seat, then using a socket and ratchet, tighten a quarter turn approx.įitting a spark plug isn’t a difficult job but some engines will be more difficult than others, V6 and 8 can be challenging as real estate is usually tight when the engine is fitted to a sedan.Screw the gasket (washered) plugs into a cold engine by hand until they seat, then using a ratchet and socket, tighten the plugs a half turn approx.But a rule of thumb for the apprentice mechanic goes something like this: In many cases, it isn’t possible and isn’t necessary.Ī mechanics answer – tighten by feel, when you do it enough times you develop a sense. But turn the engine sideways and place it in a shoebox and try to manipulate a torque wrench. Mechanics HackĪll manufacturers will recommend spark plug specs for their cars and in an ideal world with the engine on the bench that’s great. Tighten a spark plug comes with experience and over-tightening a few. You generally won’t see a mechanic use a torque wrench unless the job in question is hypersensitive to specs like wheels, large alloy front covers, alloy oil pans, cylinder heads, etc. Mechanics have as you know, a calibrated thumb that they use regularly. Tightening the plugs as you know can be successfully executed without a torque wrench. As the plug doesn’t have a washer to crush, it requires less torque to tighten, make sense? Tightening Plugs The washer is known as a crush washer and as the plug is tightened, the washer deforms to the shape of the cylinder head, making a perfect gas seal. Plugs with gaskets are pretty obvious, they’ll have a loose, but attached washer and the thread end. But the two basic types that are important when it comes to torque specification are spark plugs with gaskets and spark plugs that are tapered. Length, diameter thread type, thread reach, and heat range. There are many different types of plugs as you know. Internal spark leaking cracking of the insulator. Over-tightening can easily cause stretching which can split the threads making extraction difficult. Over-tightening the plugs causes some hard-to-fix cylinder head damage. The excess oxygen inside the cylinder and the lack of sufficient compression cause the engine to misfire and lose power.Ī loose plug and a lean cylinder run hotter, and that can cause other problems: Pre-ignition Piston and cylinder damage Valve damage Head gasket damage Plug electrode damage Damaged cylinder head threads Misfiring Lean codes Engine light on.Ī spark plug may be tightened to spec and still come loose, if that happens suspect cylinder head thread damage, plug thread damage, or incorrect plug length or heat range. When a plug comes loose, cylinder compression is lost and the cylinder inhales oxygen through the loose plug on the downstroke. It’s important they are tight, obviously, as plugs seal off the combustion chamber. Engine compression, combustion, heating, and cooling cycles can all cause the plugs to come loose if not tightened correctly. Spark plugs are right at the business end of your engine. The Importance Correctly Torqued Spark Plugs

0 kommentar(er)

0 kommentar(er)